Manufacturing

An efficient plant is one where equipment and people are working as hard as possible, right? Wrong! This is the way most supervisors and managers operate their facilities. It came from the industrial revolution, where increases in labour went directly to more production. To see how this can cause havoc in a modern plant, let’s look at a simple example.

Mom’s Cookies

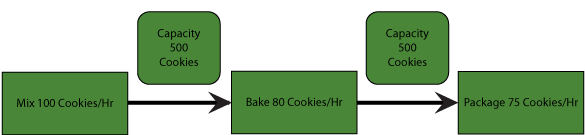

Meet Mom. She has a cookie business that is booming. Her customers love her cookies and would buy more if they could. Her three sons, Max, Ray and Pat run the three steps in the process. Max runs the mix, Ray is in charge of the Bake and Pat packages the cookies. The process looks like this.

The brothers are very competitive with each other and love to “one up” each other. They don’t talk to each other and run each part of the business independently. Although Mom is selling a lot of product, she isn’t making any profit. Some other problems:

- Max got her to spend $100,000 on a new mixer. This increased the capacity of the mix operation from 90 to 100 cookies per hour. She didn’t see an increase in cookie sales, and is worried this was a bad decision.

- Pat takes pride in being the quality control of the plant. One day, he bit into a cookie and broke his tooth. What he spit out (along with is tooth) was a bolt. The three brothers traced it back to a rotor in the mixer. They had to scrap all the inventory they had, 800 cookies.

- Mom’s banker told her that she has borrowed past her limit and was calling in some loans.

- Gerry, a local millionaire, offered Mom triple the price for a special party. The cookies were a special recipe and style. The only trouble was the party was the next week and she wasn’t able make them on time.

Can somebody help Mom? Click here to help Mom!

© Copyright 2007 - Abonar Business Consultants Ltd